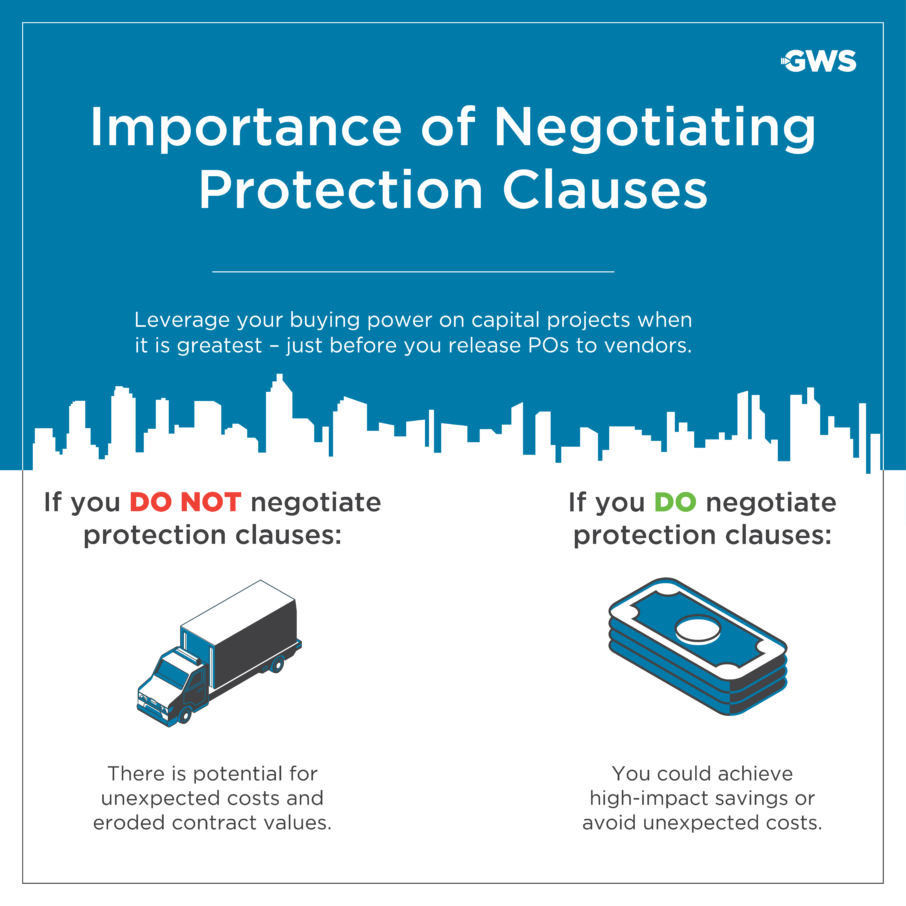

Have you ever negotiated protection clauses with vendors for new large-scale capital product shipments, warehousing, storage, and installation? Doing so can help prevent unexpected costs and delays. By negotiating these clauses when you’re buying power is greatest, you can establish important protections that could have significant hard dollar impacts on your project.

Asserting Control with Order Acknowledgement

One effective way to maintain control over your project and avoid unnecessary warehousing costs is through the use of Order Acknowledgements. By clearly communicating to vendors when you would like their orders fulfilled and shipped to your locations, it can help you prevent the common issues that occur when equipment is stored at facilities during construction.

3 Common Issues at Equipment Storage Facilities:

- Elapsing warranties for medical equipment, beginning on receipt

- Undamaged exterior shipping materials with the possibility of concealed damages

- Temptation to open items to inspect for damages and risk damaging items replaced in non-original packaging before installation

Order Acknowledgements – a Secondary Goal

With large “buys” an Order Acknowledgement is critical for multiple reasons mentioned above. Conducting the Order Acknowledgement begins immediately after the PO is sent to the vendor. At this time, a letter is delivered to the vendor clarifying Ship Date and Ship To information. The letter also leverages the significant buying power mentioned above to assert protection clauses for health systems. This is the optimal time to achieve a concealed damage waiver, warranty start at clinical acceptance, and other favorable terms for your products. The Order Acknowledgement Letter is the mechanism to achieve these important impacts within your project.

Cascading Impacts

These kinds of issues can result in missed deadlines and potentially trigger a domino effect for subcontractors/trades that make bigger impacts to project costs and timing. This is why many hospital systems hire healthcare logistics experts that work hand-in-hand with them, their team, and vendors to ensure timely equipment installation, establish protections for equipment, and handle returns of damaged items. This helps take the load off of facilities managers so they can focus on other important aspects of their current operations, all while ensuring everything is completed on schedule.

Get Connected with a Logistics Expert

GWS can help you navigate this process and ensure that your project is completed on time and on budget. Contact us today to learn more about how we can help you avoid late project surprises and cost overruns due to concealed damages.